Real-world projects.

Linia Family

During the summer of 2020, I was lucky enough to work on the prototypes of the Linia family, a line of outdoor products for Forms + Surfaces. During these months, I worked with the Director of Design to make revisions in the Solidworks design and then create a variety of Prototypes. I was able to work with multiple materials and methods of construction depending on the need of the prototype.

Below, I have documented my contribution to the product.

Form Prototyping

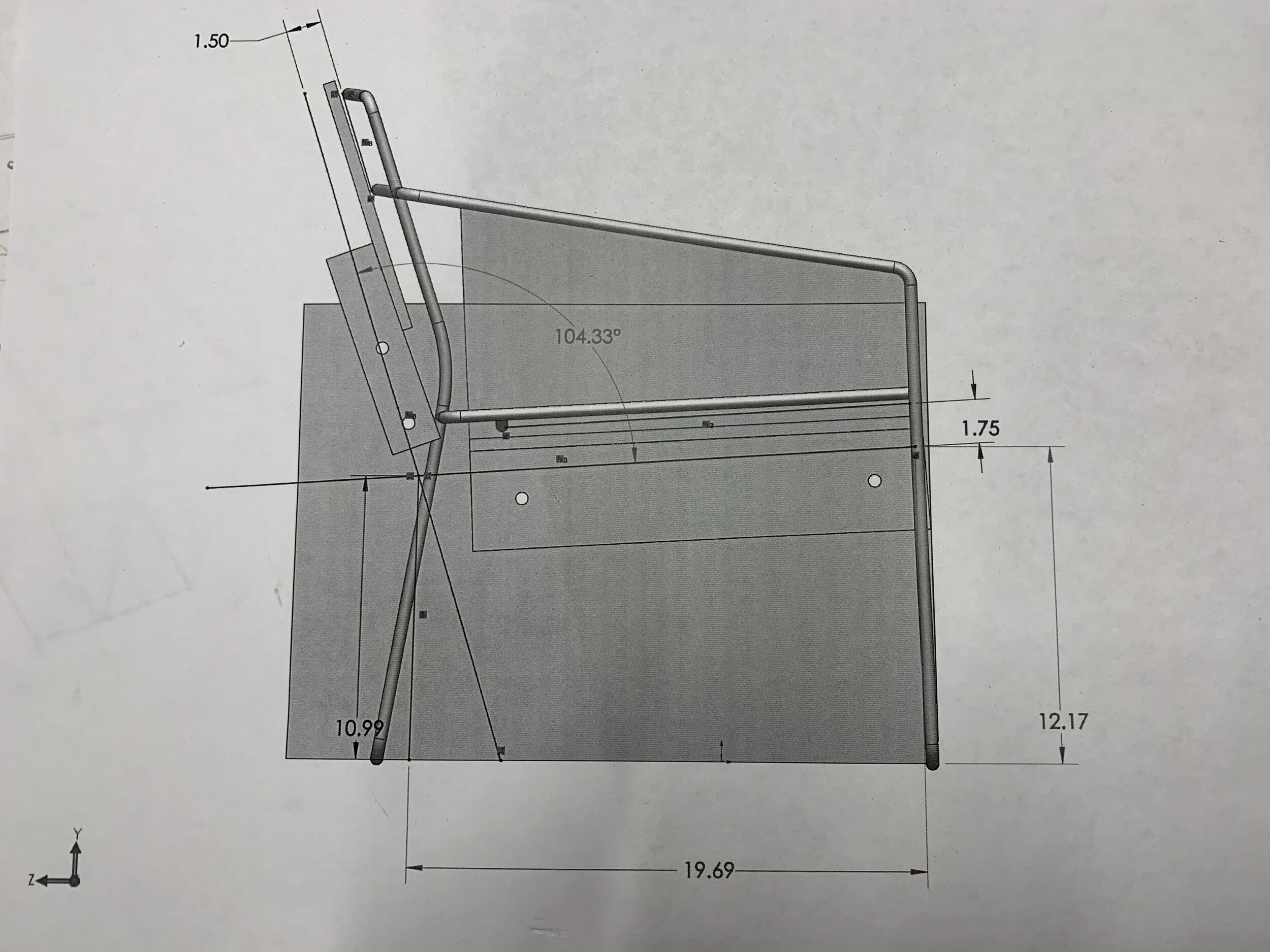

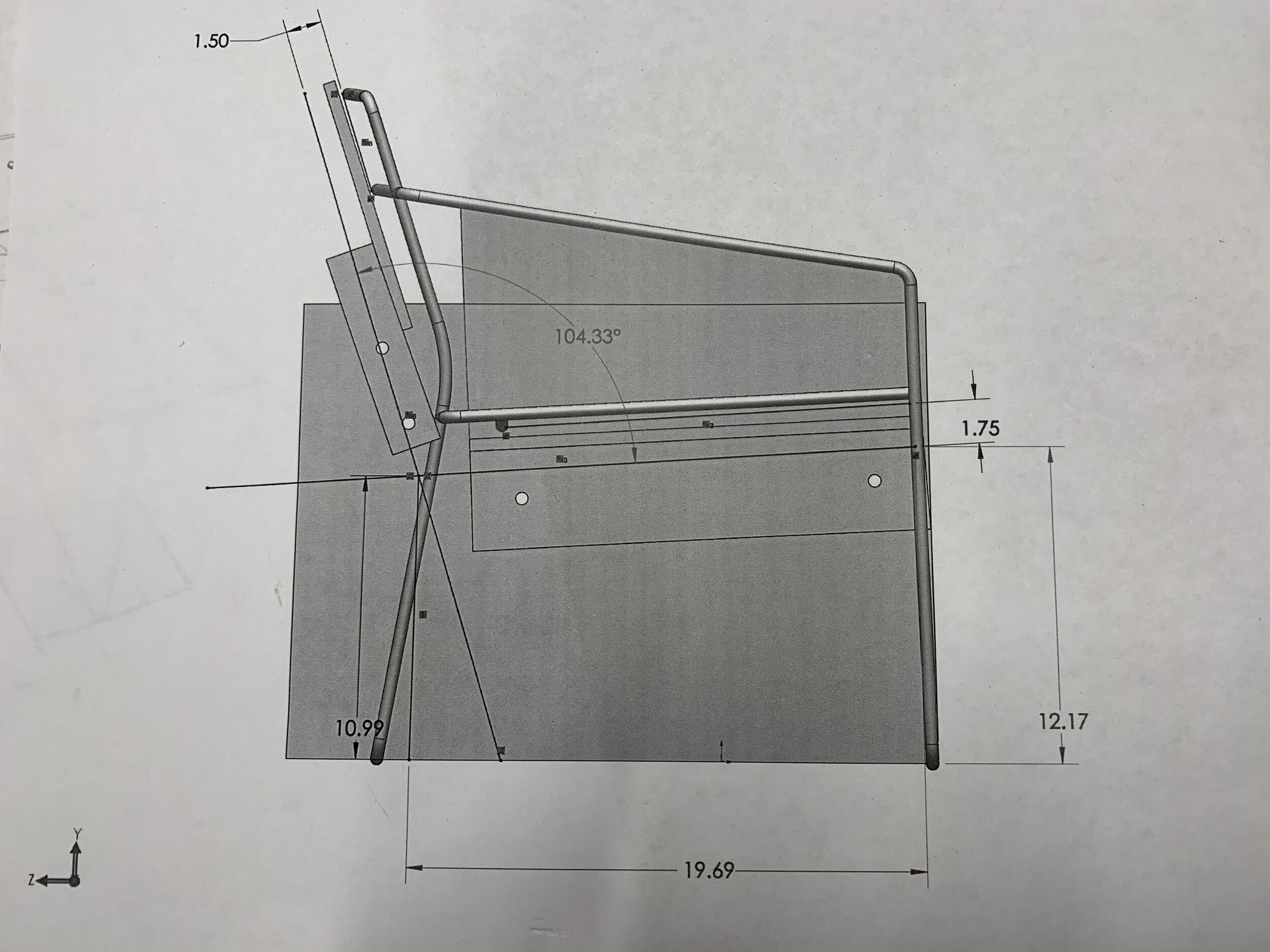

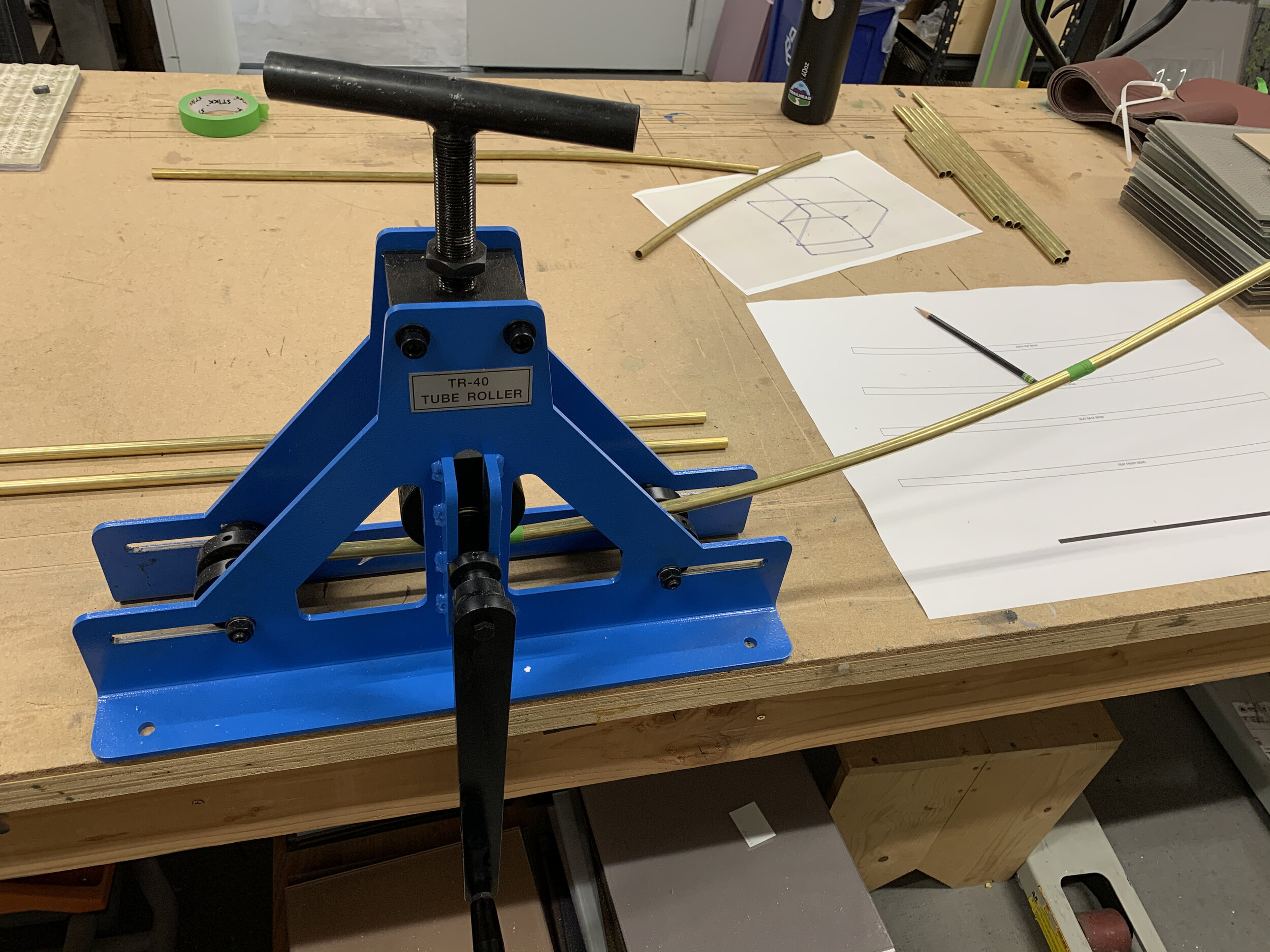

For this chair, the Director of Design, Adam Tripp, gave me technical drawings that I would use to make prototypes. I cut the brass rods to the correct dimensions and used a rod bending device to create the right shapes for the seat and chair back. For the joints, we used 3D printed connections that were assembled to the rods using hot glue.

Function Testing and Prototyping

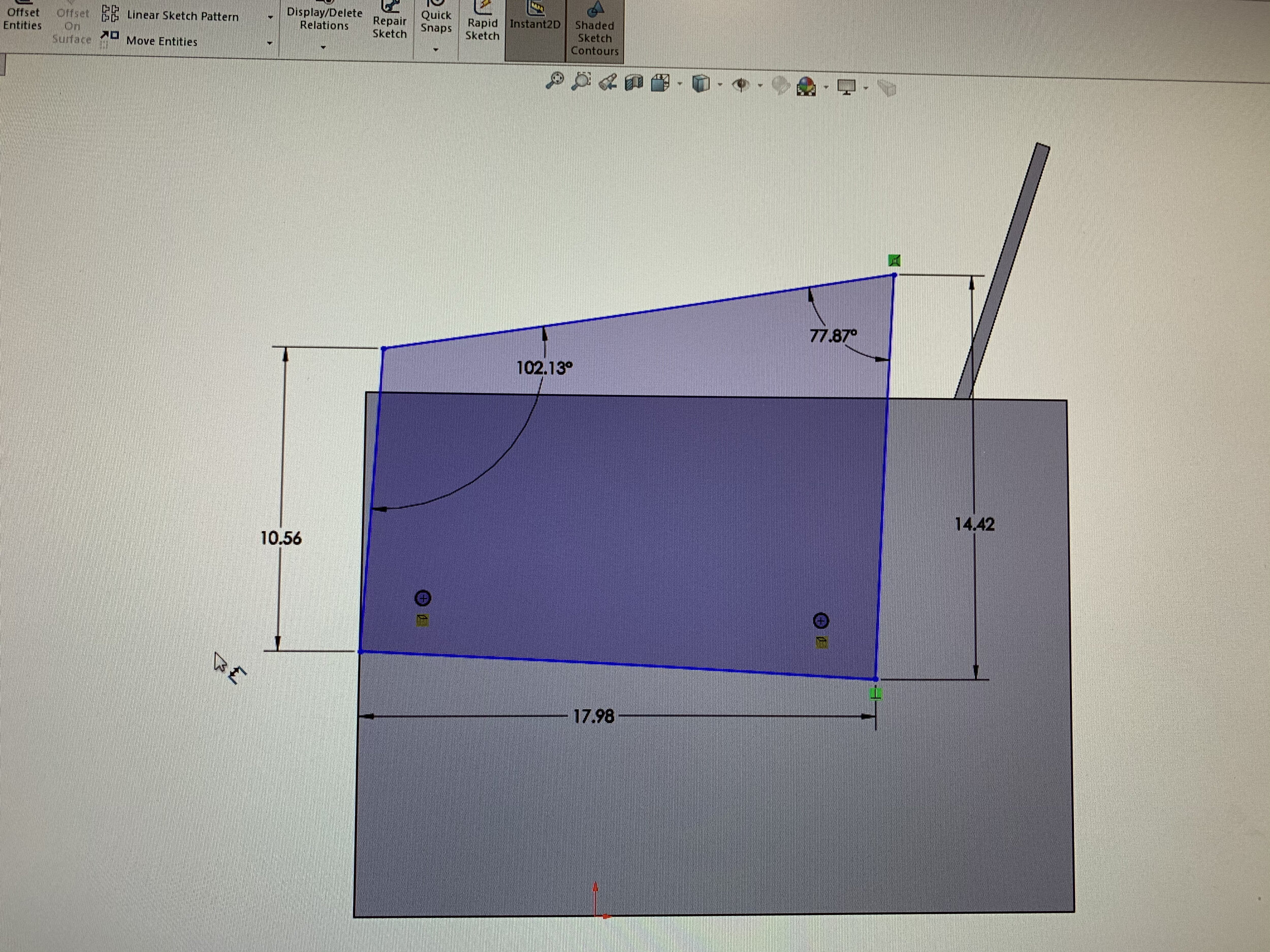

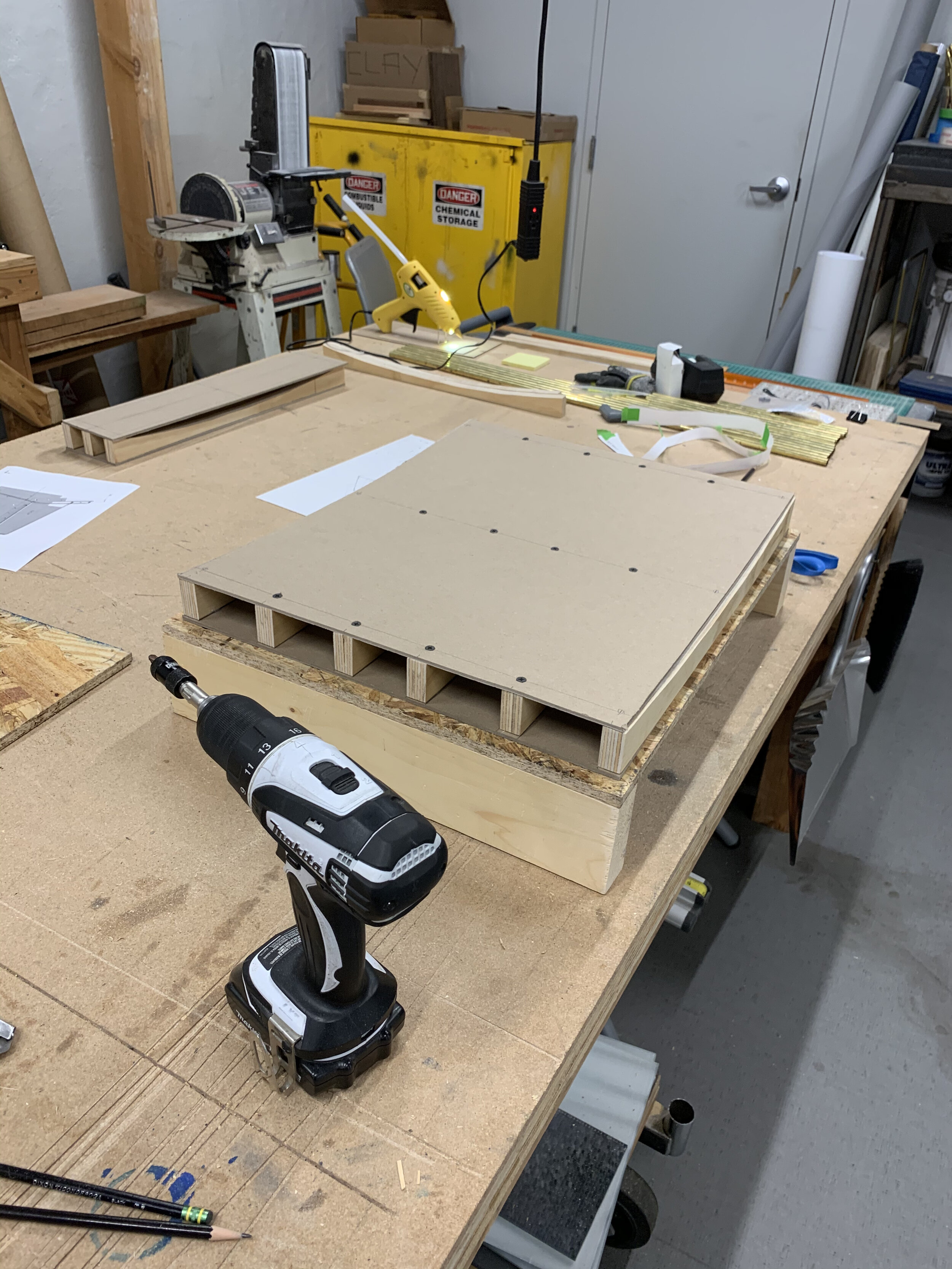

After progressing this product to a point where the design team was happy with the visual aspects of the chair, we tested the comfortability of the chair. Shown below is the process I used to create a functional prototype that could support an individual’s weight and test angles and dimensions. Depending on the results of these tests, we would make revisions as necessary.

In order to get to the final product, we had to repeat each of the processes until the chair was aesthetically pleasing and had a good ergonomic fit. Below are images of prototypes and then the final image.